Surat's Top Rated HVAC Service Provider- CALL NOW 8000392000

Air Handling Units

What is an air handling units?

The main functions of an air handling unit include:

- Air filtration: AHUs are equipped with filters to remove dust, pollen, and other airborne particles from the incoming air, improving indoor air quality.

- Heating: AHUs can have heating elements or heat exchangers to raise the temperature of the air during colder months. This can be done through the use of electric heaters, hot water coils, or steam coils.

- Cooling: AHUs can have cooling coils or refrigeration systems to lower the temperature of the air during warmer months. These coils are typically connected to a chiller or a cooling system.

- Humidification and dehumidification: AHUs can include humidifiers or dehumidifiers to control the moisture content of the air, ensuring optimal humidity levels for comfort and preventing issues such as mold growth.

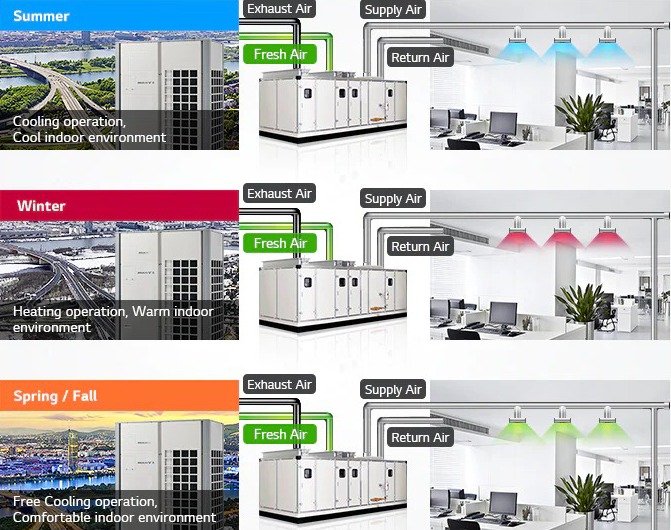

- Air mixing and circulation: AHUs use fans to draw in fresh air from the outside or recirculate air from within the building. The air is then mixed, conditioned, and distributed through a network of ducts to various zones or rooms.

- Control and monitoring: AHUs often have control systems to regulate temperature, humidity, air flow, and other parameters. Sensors and actuators help monitor and adjust these conditions based on the desired settings.

Mechanism of air handling unit

The mechanism of an air handling unit (AHU) involves several components and processes working together to condition and distribute air within a building. Here is a general overview of how an AHU operates:

Air intake: The AHU draws in outside air or recirculates indoor air through an intake section. This section typically includes filters to remove dust, pollen, and other particles from the incoming air.

Mixing chamber: In the mixing chamber, the incoming air from the intake section is mixed with the recirculated air to achieve the desired air temperature and quality. Dampers may be used to control the proportions of fresh and recirculated air.

Conditioning components: a. Heating: If heating is required, the AHU can have heating elements, such as electric heaters, hot water coils, or steam coils. The air passes over these heating elements, which raise its temperature. b. Cooling: If cooling is needed, the AHU contains cooling coils connected to a chiller or refrigeration system. The air passes over these coils, which remove heat from the air, lowering its temperature. c. Humidification/dehumidification: To control the humidity level, the AHU may include humidifiers to add moisture or dehumidifiers to remove moisture from the air.

Fan and air distribution: The conditioned air is then forced through a fan or blower, which increases its velocity. The fan helps to overcome resistance in the ductwork and ensures proper air circulation. The pressurized air is then distributed through a network of ducts to various areas or zones within the building.

Control and monitoring: AHUs have control systems that regulate various parameters such as temperature, humidity, and air flow. Sensors throughout the unit monitor these conditions, and the control system adjusts the operation of heating, cooling, and humidification/dehumidification components to maintain the desired settings.

Exhaust and return: The AHU may have exhaust sections to remove stale air from the building. Additionally, it may have return sections that collect air from different zones and return it to the AHU for conditioning and recirculation.

Throughout this process, the AHU continuously cycles and conditions the air to maintain a comfortable and healthy indoor environment. The specific mechanisms and configurations of AHUs can vary depending on the size, purpose, and complexity of the HVAC system in a given building.

Advantages of air handling units

Air handling units (AHUs) offer several advantages in HVAC systems and building environments. Some of the key advantages of using AHUs are:

Improved Indoor Air Quality (IAQ): AHUs include air filters that help remove dust, pollen, allergens, and other airborne particles from the incoming air. This filtration process significantly improves the IAQ by reducing pollutants and promoting cleaner and healthier air within the building.

Temperature and Humidity Control: AHUs can be equipped with heating and cooling components, such as coils or heat exchangers, which allow precise control over the temperature of the supplied air. They also incorporate humidification and dehumidification systems, enabling optimal humidity levels to be maintained. This ensures comfort for occupants and helps prevent issues like mold growth and discomfort associated with excessively dry or humid conditions.

Energy Efficiency: AHUs are designed to be energy efficient. They often incorporate energy recovery systems, such as heat exchangers, which transfer heat or coolness between the incoming and outgoing air streams. This helps to minimize energy consumption by pre-cooling or pre-heating the incoming air, thereby reducing the load on the heating and cooling components.

Flexibility and Zoning: AHUs can be designed to accommodate zoning within a building. Zoning allows different areas or zones to have separate temperature and airflow control, based on specific requirements. This flexibility helps optimize comfort levels in different zones and allows for energy savings by adjusting conditioning only where needed.

Air Distribution: AHUs include fans or blowers that facilitate proper air distribution throughout the building. They ensure that conditioned air reaches each area or zone effectively, maintaining uniform temperatures and air circulation. This helps eliminate hot and cold spots, ensuring consistent comfort levels.

Centralized Control: AHUs are typically centrally controlled and monitored, allowing for easy management of the HVAC system. Central control enables adjustments to temperature, humidity, and airflow settings, as well as the ability to monitor system performance, detect faults, and optimize energy consumption.

Noise Control: AHUs are designed with noise reduction features, such as insulated panels and vibration dampening, to minimize operational noise. This contributes to a quieter and more comfortable indoor environment.

Scalability and Expandability: AHUs can be designed to accommodate future expansion or changes in building requirements. They can be easily modified or upgraded to adapt to increased cooling or heating loads, additional zones, or changes in system configurations.

Overall, air handling units provide efficient and effective conditioning and distribution of air, leading to improved indoor comfort, better IAQ, energy savings, and greater control over the HVAC system.

Disadvantages of air handling units

While air handling units (AHUs) offer various advantages, there are also some potential disadvantages associated with their use. Here are a few drawbacks to consider:

Initial Cost: AHUs can be expensive to install, especially in larger buildings or complex HVAC systems. The cost includes not only the unit itself but also associated components, such as filters, fans, coils, control systems, and ductwork. The initial investment required for AHUs may be higher compared to other HVAC systems.

Space Requirements: AHUs typically require a dedicated space within the building to accommodate their size. This space should be adequately ventilated and accessible for maintenance and repairs. In some cases, the available space in a building may limit the installation of AHUs or may require modifications to accommodate them.

Maintenance and Operation: AHUs require regular maintenance to ensure optimal performance and energy efficiency. Filters need to be cleaned or replaced, coils should be inspected and cleaned, and fans and motors need regular servicing. The complexity of AHUs and the need for specialized maintenance can increase maintenance costs and downtime if not properly managed.

Energy Consumption: While AHUs can be energy-efficient, improper design or operation can lead to increased energy consumption. Inefficient air distribution, inadequate insulation, or improper control settings can result in excessive energy usage. Regular monitoring and optimization of AHU performance are necessary to minimize energy consumption.

Noise: AHUs can generate noise due to the operation of fans, motors, and air movement within the unit. Without proper noise reduction measures, the noise generated by AHUs can be a concern, especially in noise-sensitive areas or buildings where a quiet environment is desired.

Limited Control in Mixed-Use Buildings: In buildings with multiple uses or varying occupancy schedules, it can be challenging to achieve optimal comfort and energy efficiency throughout the entire building using a single AHU. Different zones may have different temperature and ventilation requirements, and a single AHU may not provide the flexibility needed to cater to these diverse needs.

Dependency on Centralized System: AHUs are typically part of a centralized HVAC system, and if the AHU fails or requires maintenance, it can impact the entire system. This dependence on a single unit can lead to disruptions in airflow, temperature control, and overall comfort if adequate redundancy or backup measures are not in place.

It’s important to note that while AHUs have their disadvantages, proper design, installation, and maintenance can help mitigate these drawbacks and ensure their effective and efficient operation.

Industrial air handler hire to suit any requirement

Vipul Ac provide a range of AHUs – air handling units. Industrial air handling units are systems designed to provide large scale temperature control by circulating warmed or cooled air. Industrial air handling units come in a wide range of sizes, from 50 kW to 500 kW – we have the kit to fit the requirements of any application.

Our service offers industrial air handling units that are ideal for open spaces – whether you need bulk cooling for storage or distribution facilities, or comfort cooling for offices and factories.